The FMCG industry in India is growing faster than ever, and FMCG supply chains are at the heart of this growth. From chips to cookies, namkeen to sweets, customers now expect products to be fresh, easily available, and delivered quickly. To meet these expectations, companies need strong and smart FMCG supply chains in India — ones that balance speed, reach, and technology. At Priniti Foods, we’ve built our supply chain to make sure every product — whether it’s chips, namkeen, chachare, fryums, rusk, cookies, or traditional sweets — reaches customers fresh, on time, and in perfect condition. Here’s how we do it.

1. How Our FMCG Supply Chain Works

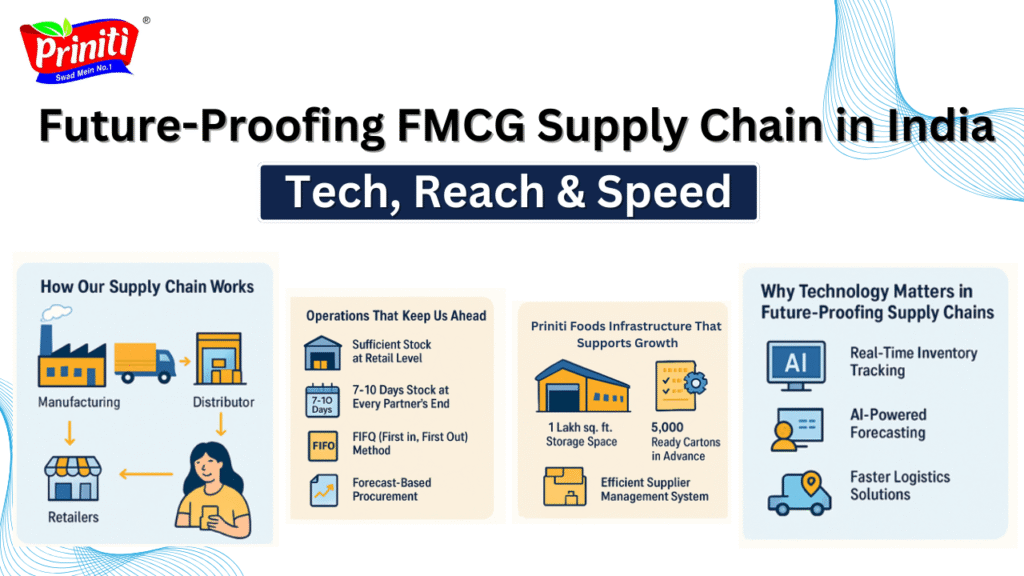

The journey of every product at Priniti Foods is simple yet efficient:

- Manufacturing: All our products are made in-house at our production facility — from crispy snacks to melt-in-mouth sweets.

- Distribution: Once ready, goods are sent to our network of trusted distributors across India.

- Retail Reach: Distributors supply the products to retailers in different regions.

- Consumer Access: Retailers sell directly to consumers, ensuring our products are always within reach.

This structure allows us to maintain product quality, freshness, and fast delivery while keeping costs in check.

2. Operations That Keep Us Ahead

We follow FMCG supply chain management practices that ensure efficiency at every step:

- Sufficient Stock at Retail Level: Retailers always have enough stock to meet customer demand.

- 7–10 Days Stock at Every Partner’s End: Each distributor and retailer maintains a healthy stock level to avoid shortages.

- FIFO (First In, First Out) Method: This ensures older stock is sold first, keeping products fresh for customers.

- Forecast-Based Procurement: We use demand forecasts to plan procurement, preventing overstocking or shortages.

3. Infrastructure That Supports Growth

Our supply chain is backed by strong infrastructure:

- 1 Lakh sq. ft. Storage Space to handle large inventories.

- 5,000 Ready Cartons in Advance for quick dispatch during peak demand.

- Efficient Supplier Management System that helps us track and coordinate with partners easily.

4. Why Technology Matters in Future-Proofing Supply Chains

As customer expectations grow, technology is the key to making FMCG supply chains faster and smarter. For the future, companies like ours are focusing on:

- Real-Time Inventory Tracking for better stock control.

- AI-Powered Forecasting to predict demand accurately.

- Faster Logistics Solutions for timely deliveries, even in remote areas.

By combining tech, reach, and speed, we ensure our supply chain is ready for the future.

Conclusion

A strong FMCG supply chain in India is the backbone of any successful brand. At Priniti Foods, our efficient supply chain management, reliable supplier network, and smart inventory practices ensure customers get the freshest snacks and sweets every time.In the future, with the help of technology and better supplier management systems, we aim to make our supply chain even more agile, faster, and customer-focused.

FAQs:

Q1. What products does Priniti Foods offer?

Priniti Foods makes a wide range of snacks and sweets — including chips, namkeen, chachare, fryums, rusk, cookies, and traditional Indian sweets.

Q2. How does Priniti Foods maintain product freshness?

We follow the FIFO (First In, First Out) method and ensure every retailer has fresh stock ready for customers.

Q3. What is special about Priniti Foods’ FMCG supply chain in India?

Our supply chain is built on speed, reach, and technology — from in-house manufacturing to timely delivery across India.

Q4. How much storage capacity does Priniti Foods have?

We operate with 1 lakh sq. ft. of storage space and keep 5,000 cartons ready for fast dispatch.

Q5. What role does technology play in Priniti Foods’ supply chain management?

We use forecasting, real-time inventory tracking, and efficient supplier management systems to keep operations smooth.